From Sprockets to Idlers: The Total Solution for Reliable Undercarriage Parts

From Sprockets to Idlers: The Total Solution for Reliable Undercarriage Parts

Blog Article

Make Best Use Of Performance With Resilient Undercarriage Components

In the world of heavy machinery and devices, the role of undercarriage parts is vital in ensuring ideal efficiency and durability. The effectiveness and efficiency of these parts can considerably influence the overall operation of equipment, making the option of sturdy undercarriage parts an essential decision for supervisors and drivers alike. By exploring the elaborate relationship in between sturdiness and efficiency in undercarriage components, a deeper understanding of the subject arises, clarifying the critical variables that drive functional success. As we browse through the intricacies of undercarriage maintenance, element, and long life option, an extensive exploration waits for to introduce the key strategies for accomplishing peak performance in sturdy applications.

Advantages of Utilizing Durable Undercarriage Parts

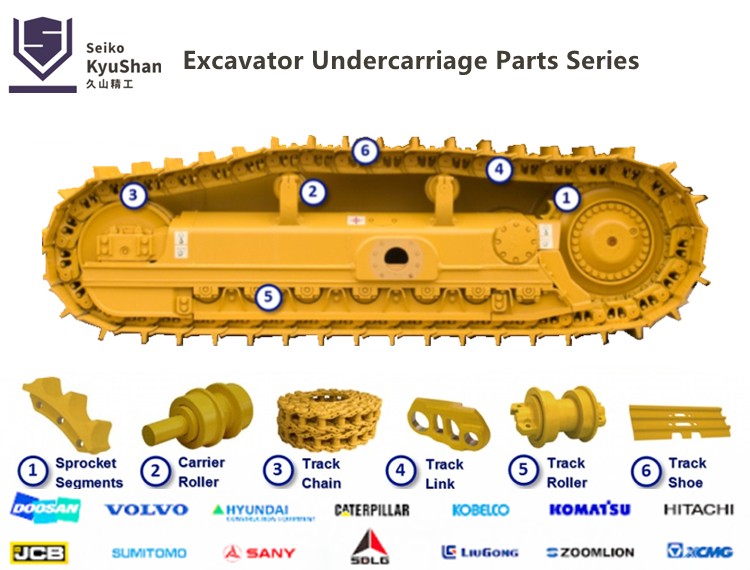

Utilizing durable undercarriage parts not only boosts the durability of hefty equipment but also reduces maintenance expenses considerably. By purchasing high-grade undercarriage components, such as tracks, gears, idlers, and rollers, devices operators can experience boosted uptime and boosted total efficiency.

Additionally, the longevity of hefty machinery is directly linked to the high quality of its undercarriage components. Resilient parts can endure the roughness of requiring applications, making sure that the devices stays functional for extensive periods. Because of this, drivers can prevent pricey downtime and upkeep costs, inevitably optimizing the return on financial investment for their equipment.

Aspects Affecting Undercarriage Durability

The durability of undercarriage parts in heavy equipment is affected by different important elements that directly effect efficiency and durability. One of the key elements impacting undercarriage toughness is the quality of materials utilized in production. Top notch products, such as hardened steel, are crucial for withstanding the extreme problems and hefty tons that undercarriage parts undergo. Appropriate upkeep techniques likewise play an important function in identifying the life-span of undercarriage components. Routine examinations, lubrication, and timely replacement of worn-out components can considerably expand the sturdiness of the undercarriage.

Furthermore, ecological elements can have a considerable effect on the long life of undercarriage parts. Exposure to rough products, extreme temperature levels, and extreme working problems can speed up wear and tear on undercarriage components. Choosing undercarriage parts that are especially designed to withstand these environmental difficulties is crucial for guaranteeing resilience.

Furthermore, the style and engineering of undercarriage parts have a direct influence on their toughness. Components that are created to distribute tons evenly, reduce friction, and lessen stress and anxiety concentrations are more probable to have a much longer life-span - undercarriage parts. By taking into consideration these critical factors, tools operators can make best use of the resilience and performance of their undercarriage elements

Upkeep Tips for Prolonging Undercarriage Life

Carrying out regular maintenance regimens is important for expanding the lifespan of undercarriage parts in heavy machinery. To extend the undercarriage life, it is crucial to regularly evaluate for deterioration. On a regular basis look for loose or missing screws, harmed rollers, or misaligned tracks, as these issues can intensify and trigger more damage otherwise dealt with immediately. Furthermore, guarantee that the undercarriage is correctly lubricated according to maker standards to minimize rubbing and stop premature wear.

One more important maintenance pointer is to keep the undercarriage tidy from dust, rocks, and debris. Accumulation in the undercarriage can accelerate wear and rust, leading to expensive fixings. Cleaning the undercarriage after procedure in harsh conditions is recommended to stop these concerns.

Finally, monitoring and recording maintenance tasks can help in creating an aggressive maintenance schedule. Maintaining comprehensive documents of replacements, examinations, and repair work can offer useful understandings right into the undercarriage's condition and performance over time, assisting in anticipating and avoiding prospective failings. By following these upkeep pointers faithfully, drivers can dramatically increase the resilience and performance of undercarriage components in heavy machinery.

Choosing the Right Undercarriage Components

Selecting ideal undercarriage elements is critical for maximizing the performance and durability of hefty i was reading this machinery. When it comes to selecting the ideal undercarriage elements, there are a number of variables to consider.

In addition, thinking about the top quality and track record of the maker is vital. Deciding for trustworthy brands understood for generating high-performance and long lasting undercarriage parts can substantially impact the total efficiency and long life of the machinery. Guaranteeing that the components are suitable with the maker version and correctly mounted is essential for optimum efficiency. By carefully selecting the appropriate undercarriage elements, tools owners can improve efficiency, decrease downtime, and extend the lifespan of their hefty equipment.

Case Studies: Enhanced Performance With Sturdy Parts

Including long lasting undercarriage components has actually shown considerable improvements in machinery efficiency. One case research included a building company that updated its excavator's undercarriage elements to more long lasting options. The firm observed a significant decrease in downtime because of undercarriage maintenance, leading to boosted performance and cost savings. The durable parts withstood severe working problems, decreasing damage substantially.

In an additional circumstances, a mining procedure replaced the undercarriage parts of its excavator with top quality, sturdy choices. This switch brought about an exceptional renovation in the bulldozer's ability to move and total performance. The maker could browse difficult surfaces more successfully, bring about boosted functional effectiveness and decreased gas intake.

Furthermore, a logging business purchased long lasting undercarriage components for its forestry tools. The upgraded parts exhibited long term life-span and raised go to my blog resistance to abrasion from rough surface. As a result, the company experienced reduced upkeep prices and enhanced equipment uptime, inevitably enhancing its lower line. These case research studies emphasize the concrete benefits of making use of resilient undercarriage components in enhancing machinery performance and durability.

Final Thought

Finally, utilizing sturdy undercarriage components can substantially enhance performance and long life Check This Out of hefty machinery. Variables such as appropriate upkeep and selecting the ideal elements play a critical duty in maximizing undercarriage resilience. By executing these approaches, businesses can lower downtime, increase efficiency, and ultimately reduce operational costs. Study have actually shown that buying durable undercarriage components can lead to boosted total efficiency and performance in numerous sectors.

The efficiency and efficiency of these components can substantially influence the general procedure of equipment, making the selection of durable undercarriage components a critical decision for managers and operators alike.Including resilient undercarriage parts has actually demonstrated significant improvements in machinery efficiency. These instance research studies emphasize the tangible advantages of using resilient undercarriage components in optimizing equipment efficiency and long life.

In verdict, utilizing durable undercarriage parts can significantly boost performance and longevity of heavy equipment (undercarriage parts). Case research studies have actually revealed that spending in resilient undercarriage components can lead to boosted total performance and productivity in various sectors

Report this page